- Architectural Project / arch. M. Varratta

- Structures / Studio ing. P. Costa - Genoa

- Plant / ing. Sandro Morandi Associati & CVD Projects - Genoa

- Construction Management / geom. L. Delehaye

- Building Company / Delucchi Costruzioni - Genoa

The realization of the project of the detached villa built in Genoa-Nervi, bears the signature of the Genoese architect Maurizio Varratta. This is a housing project of quality and sustainability that combines respect for nature and the surrounding urban environment, despite a modern image and the use of recycled and recyclable natural materials (and a strong innovative character).

Zintek® titanium-zinc roofing gives the building a clean, elegant silhouette in which all elements blend harmoniously.

In the realization of this eco-sustainable and eco-friendly building, the ventilated roof, reminiscent of an inverted keel, made of titanium-zinc, has contributed to the achievement of excellent aesthetic and functional results, thanks to the intrinsic characteristics of zintek® – including ductility, durability, sustainability and total recyclability. Not to mention that in view of the peculiarity of the type of coating, the photovoltaic and solar thermal panels, now essential for the achievement of the required sustainability parameters, integrate and harmonize with the roof itself, in compliance with the landscape and urban constraints imposed by the rules of government of the territory.

We explored the issues of the project directly with architect Varratta.

The intervention has important intrinsic value. From the point of view of urban planning and construction we have operated in a very sensitive area of the municipality of Genoa, subject to landscape constraints and integrated in a established historical fabric. We were able to design and build a modern building in compliance with the parameters indicated by the Municipality by introducing, given the shape of the roof, zinc as a coating and finish, as an alternative to the use of slate and tile, materials already widely present in the existing historical fabric. The feedback has been very positive, not only for those involved in the project, but also for the Municipality of Genoa, since, thanks to its peculiar characteristics of appearance, aging and oxidation, zinc has made the building integrate perfectly with all its surroundings, harmonizing with the landscape and the other buildings, without ever entering in contrast with the existing building fabric, despite the unconventional shape of the new building.

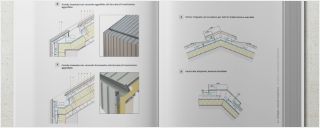

As an architectural firm, we recently discovered zintek® as a building material. We had already used metal roofing in the past, but with poor technical and architectural results. Titanium-zinc has the characteristic of being a natural material, therefore easier to integrate aesthetically, but at the same time, thanks to special installation techniques, allows for high performance of water tightness and external closure and lends itself easily to be used as a roof of a building of value. The decision to use this type of roofing has allowed us, moreover, on the one hand to increase the energy performance of the building, improving the thermal insulation against the realization of a ventilated roof, and on the other hand to increase the aesthetic performance, incorporating the photovoltaic and solar thermal panels in a simple and harmonious way. The same applies to lifelines, thanks to the use of special accessories for seaming.

In a traditional roof, in slate or brick, the inclusion of these plant engineering and safety components, now indispensable, would not have allowed us to obtain the same technical-aesthetic result guaranteed by titanium-zinc and we would have risked creating a sort of “frankenstein”. This is because, in spite of the maximum effort to look for possible solutions to allow the assembly of the above elements, the necessary cable and piping crossings would have been aesthetically unsatisfactory. Not to mention the problems related to the technical difficulty of being able to seal, after assembly, all the holes previously made to ensure water tightness.

The same reasoning can be applied to windows provided on sloping roofs: in fact, either you try to make complicated dormer windows, or the simple installation of flush windows, such as Velux, remains complex and especially difficult. While with a titanium-zinc roof, by applying specific details, you can easily achieve a good result, which resembles a modeling of the roof itself and not an added element.

Zinc brings me back to the concept of naturalness, because by its very essence it is a natural material; it doesn’t feel contrived, as could happen when using other types of metals, many of which require additional treatments such as pre-coating, age very quickly and get worse as they age aesthetically.

On the contrary, zinc improves as it ages, it has a natural and unchanging color, it always maintains its ease of processing and because of these characteristics we are proposing it in other projects we are carrying out in Milan, even in delicate contexts.

For our way of practicing architecture it is a very versatile material, which lends itself to countless types of processing; it surely requires a particular ability to develop certain details for its application, but this represents the peculiarity of a tailor-made and artisan management of the architectural project. There are no limits to its use, provided that you have a good knowledge of the material, its characteristics and application techniques, and that you then carry out an accurate assembly that respects the application and joining parameters required by the material itself.

I’m going to say something perhaps obvious, but it’s the truth: in designing a new building what counts is transparency with the supervisory bodies and the willingness and commitment to succeed in implementing the proposed project with the utmost respect for the rules. This certainly does not mean to construct a building by duplicating, in its shapes and materials, those already present in the surrounding area of the project, thus restricting one’s own ability to express oneself. On the contrary, it means to realize a project that respects the “genius loci“, through a deep knowledge of the rules and their interpretation.

In this case, as in others, what really counts is being able to build a virtuous and transparent dialogue with institutions and supervisory bodies, working through a participatory process, perhaps difficult and complicated, but in the end rewarding for the result obtained, which at times has been achieved even with solutions that might initially seem incompatible.

The trust that comes with intellectual honesty, professionalism and respect allows, as in this case, to achieve almost impossible results thanks to the team that can be created between all the professionalism and the bodies of approval and control.

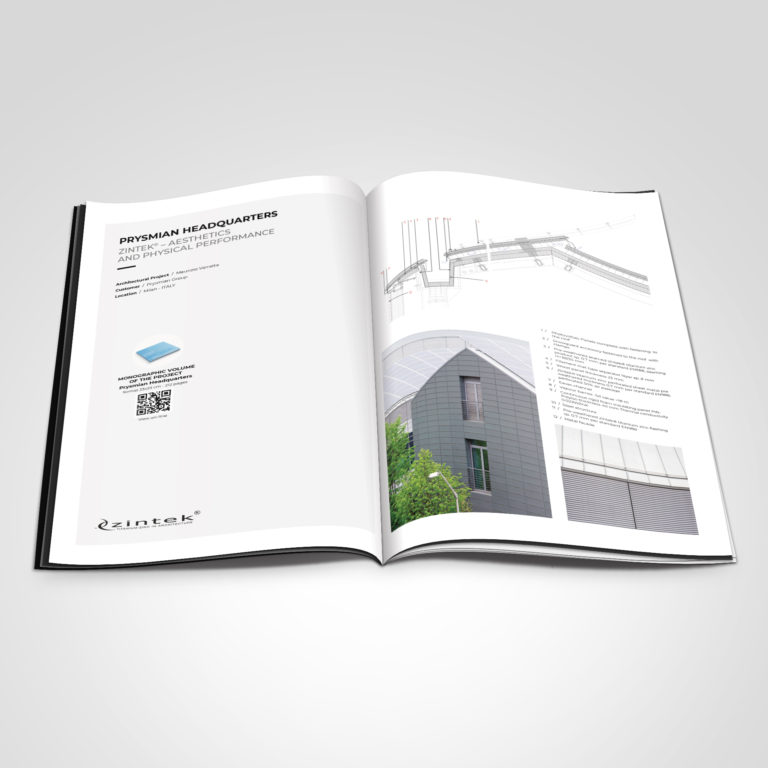

Yes. We designed the new headquarters of Prysmian Group, in the Bicocca district of Milan. A huge, very important renovation, for which we made all the roofing in zintek® titanium-zinc. It is a former industrial building, converted to offices, almost completely self-sufficient from the energy point of view, which has received many awards in the architectural field for its integration with nature, thanks to the bio-climatic greenhouses, for the use of materials and for its eco-sustainability. Even today, three years after its realization, it is still successful thanks to the materials used.

I would also like to add an aspect that has always belonged to us and that has progressively become fundamental in all the projects we tackle in the studio: I am referring to a sort of prefabrication of architectural components that we design and that often leads us to create buildings constructed elsewhere and then assembled dry on site. This process, which starts with the initial concept and ends with the production of details in 1:1 scale, allows us to have a very strong control on the quality of the buildings we realize.

With this kind of methodological approach it is easy to understand that a roof made of titanium-zinc zintek® is well suited to be used, because it can be mounted in a short time, on structures already prepared.

To conclude, I would also like to point out that the versatility and malleability of this material has allowed us to try to use it to make false ceilings and wall coverings with excellent results and that we are now trying to use it for other solutions and components to be used in our next projects.

Once again the titanium-zinc zintek® confirms itself as a “magic” material, able to bring to architectural projects – from small-scale interventions to large-scale redevelopment projects – a solidity and durability typical only of a metal roof, but also a unique style and harmony.