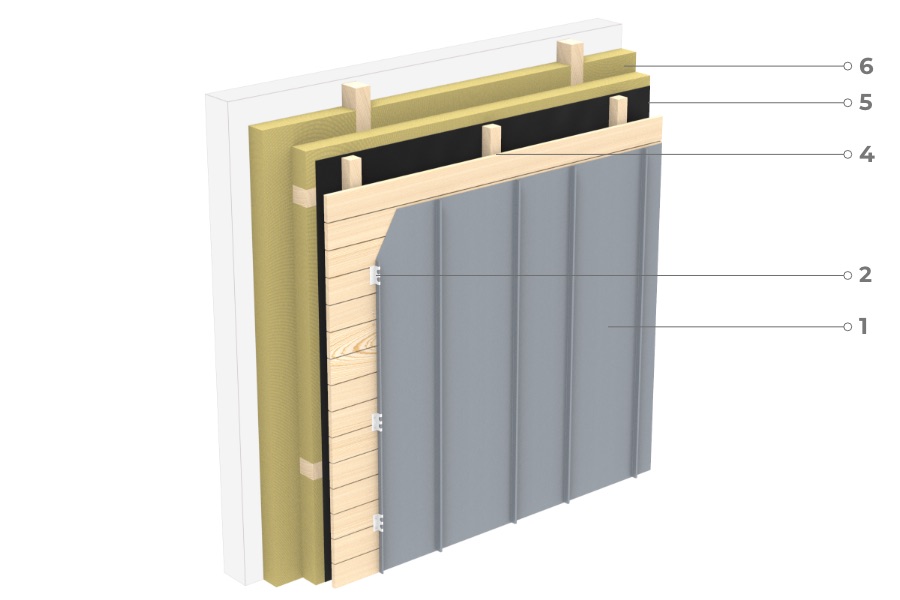

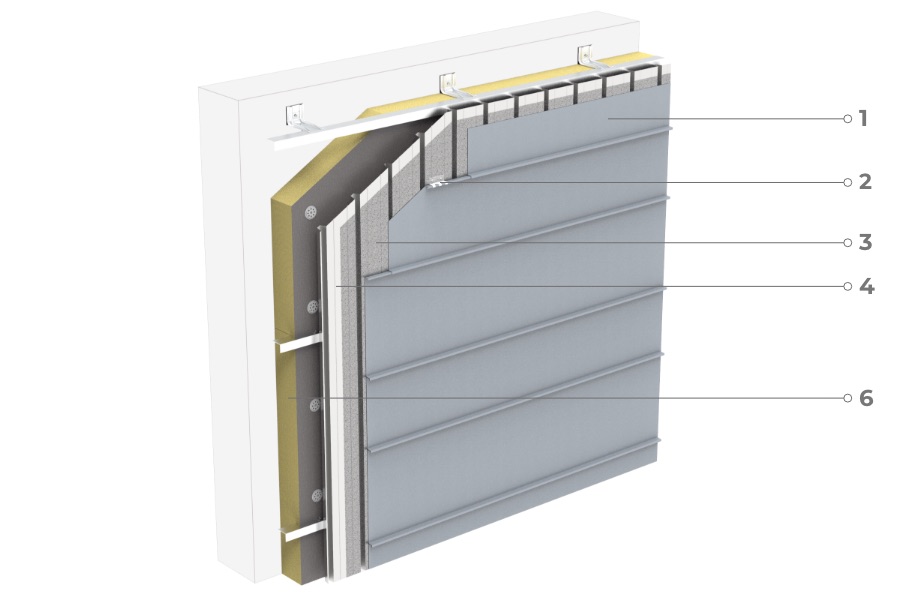

Angular seam façade system

—

The angular seam façade system can be used with horizontal, vertical or tilted joints.

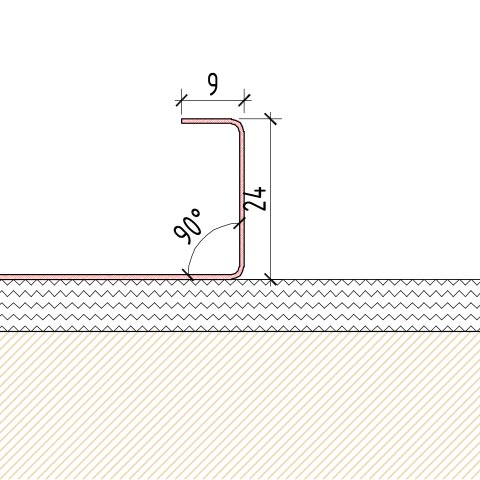

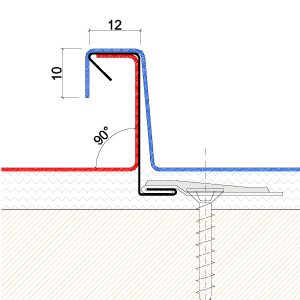

From a visual point of view, the angular seam has a height of 12 mm.

Seaming allows for the joining of profiled slabs via superimposing and folding of their edges.

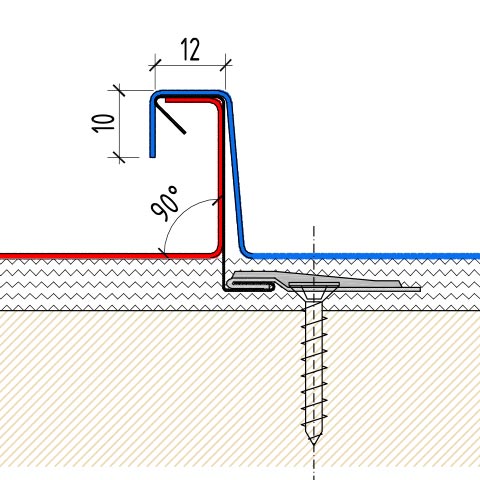

The slabs are fastened to the substructure by using concealed clips.

SUBSTRUCTURE TYPES

- WOOD

- METAL

JOINT TYPES

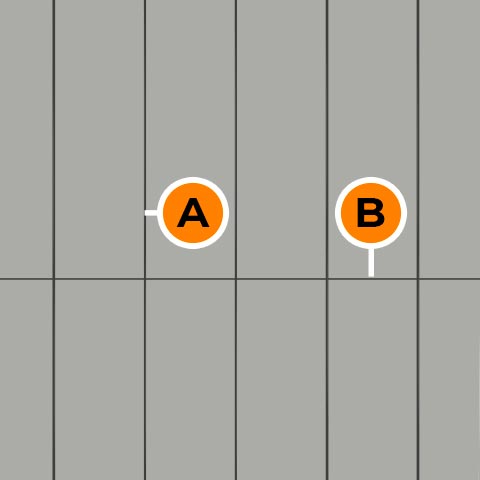

A. ANGULAR SEAM

LONGITUDINAL JOINT

B. SIMPLE COUPLING

TRANSVERSAL JOINT

EXAMPLES OF INSTALLATION SCHEMES

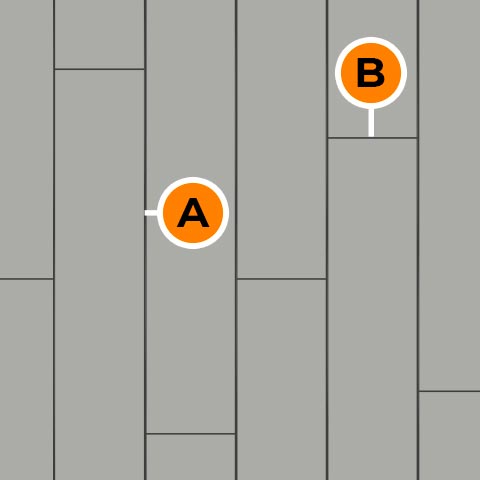

CONTINUOUS SEAM AND ALIGNED TRANSVERSAL JOINTS

CONTINUOUS SEAM AND STAGGERED TRANSVERSAL JOINTS

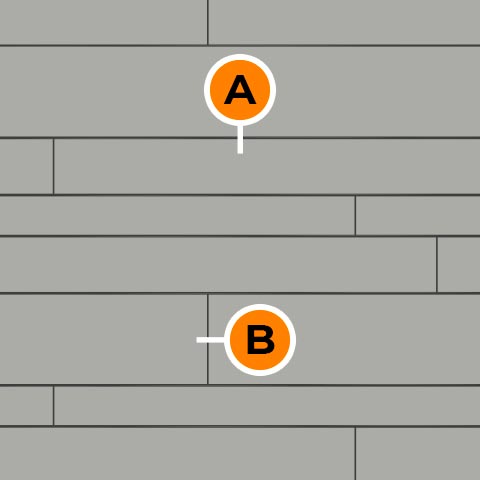

STAGGERED SEAM AND STAGGERED TRANSVERSAL JOINTS

ANGULAR SEAM SYSTEM ASSEMBLY PROCESS

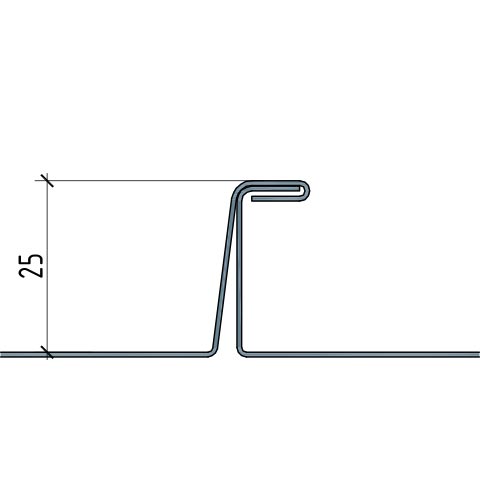

Step - 1

Installation of zintek® profiled slab H=25

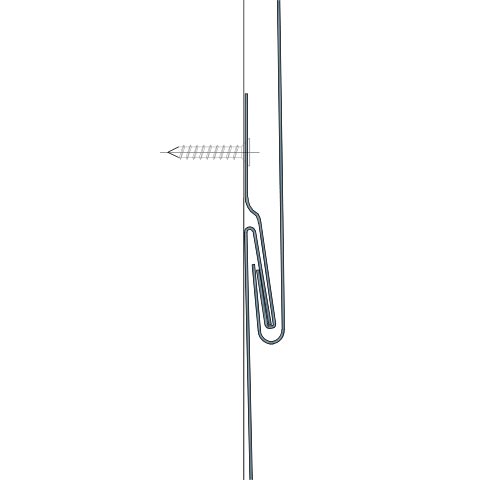

Step - 2

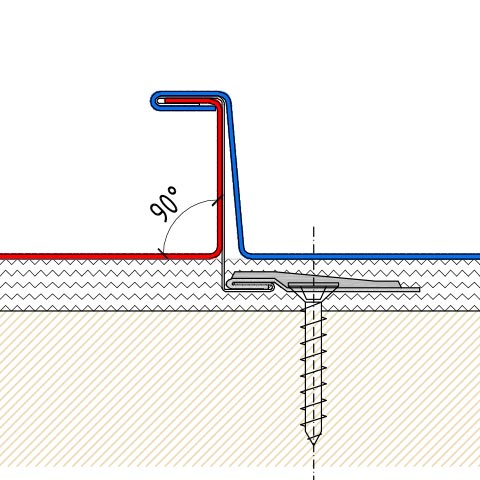

Installation of sliding clip and fastening with screws

Step - 3

Installation of overlapping zintek® profiled slab

Step - 4

Angular seam

TECHNICAL SPECIFICATIONS

USE

Internal and external façade and ceiling cladding

SUBSTRUCTURE

Raw spruce wood planking, corrugated sheet metal, three-ply solid wood panels, cement wood panels.

PITCH SLOPE

≥ 46.6% (≥ 25°)

FORMATS

Standard spacing:

480 mm

Other available measures:

260, 300, 430, 500 mm

THICKNESS

0.7 - 0.8 mm