The EMERGENCY Pediatric surgery center of excellence in Uganda

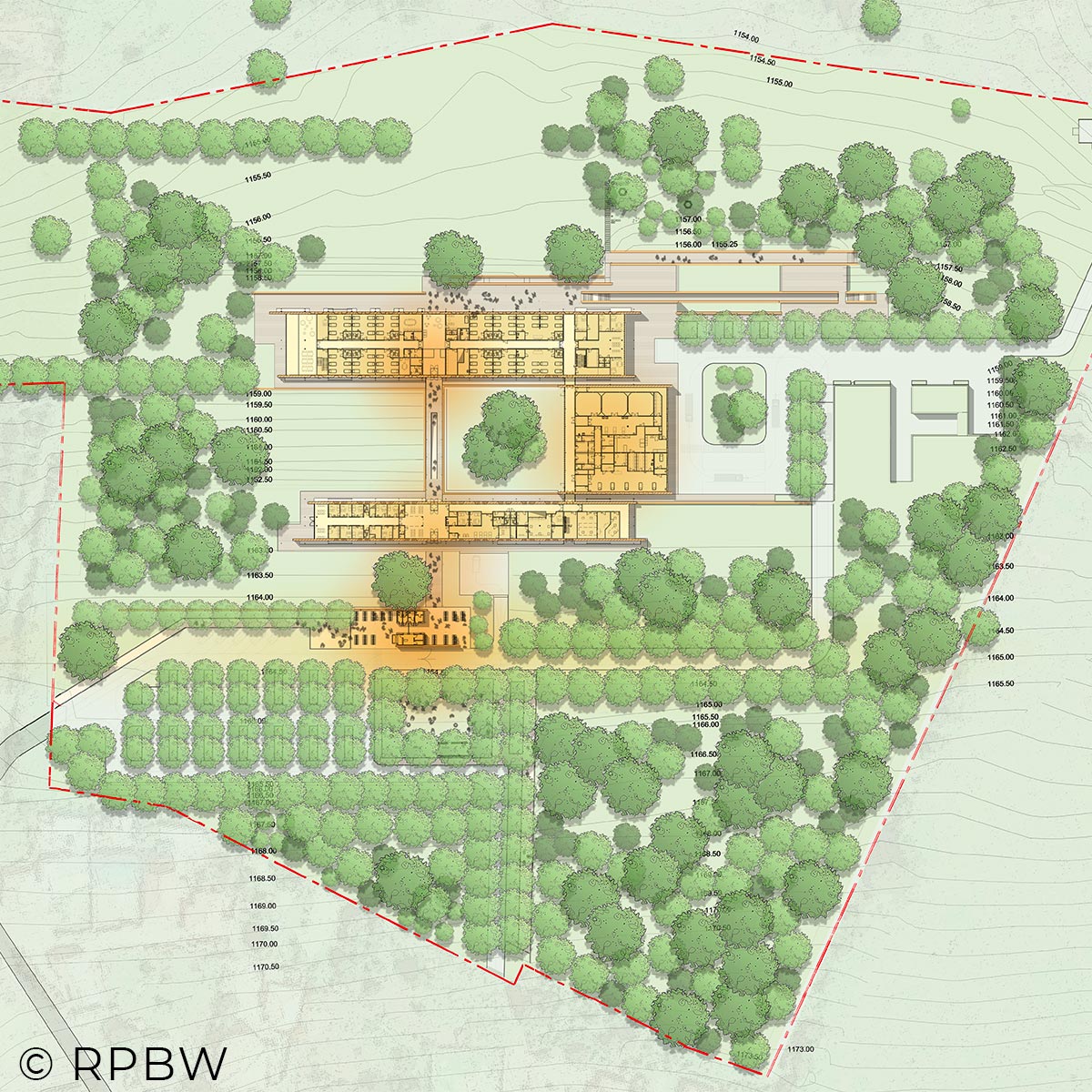

The construction of the new Pediatric surgery center began in February 2017 in Entebbe, on the shores of Lake Victoria, on a 120,000 sq m area provided by the Ugandan government.

The RPBW studio designed the hospital alongside TAMassociati and the EMERGENCY Building Division, who had previously collaborated on projects in some of the most critical areas of the planet, from Afghanistan to central Africa, Sudan and Iraq.

The structural conception of the pisé walls was supported by Milan Ingegneria, while Zintek supplied the titanium zinc roofing envelope.

From design to construction

In addition to its access and health education area, 50 hospitalization beds, 16 sub-intensive spaces, 6 intensive care beds and 3 operating theaters featuring all the necessary diagnostic and auxiliary services, the hospital also features a laboratory, a blood bank, a pharmacy, a canteen and a laundry service.

In preparation for the arrival of patients from different countries, the structure also features a guesthouse with 42 beds for patients and their relatives.

The complex also has an outdoor playground and a garden with no less than 350 trees: green areas are considered an important element for patient recovery and healing.

The edification of the structure followed the process shared by all hospitals developed by EMERGENCY: all choices concerning the construction of a new hospital are made alongside the people who have lived and will live the daily existence, management and control of the structure. Thus, the doctors of the various wards (operating theaters, intensive care, hospitalization, etc.) are involved in discussions with the architects, to set out both needs and priorities.

The particular geographic context of this project led to the development of solutions capable of combining available resources, simplicity in terms of utilization and durability over time, in accordance with what Renzo Piano has often called the law of “harsh necessity”. The need to operate with the available resources transformed the work site into a form of didactic workshop, giving birth to an approach and a protocol that can also be applied to other specific situations.

The masonry structure is built with pisé earth, a traditional technique reinterpreted in cutting edge fashion, using raw earth to ensure thermal inertia capable of keeping the temperature and humidity within the building constant. The mechanical resistance of the earth was improved with the design mix, achieving ten times its typical values and reaching the levels of high quality concrete.

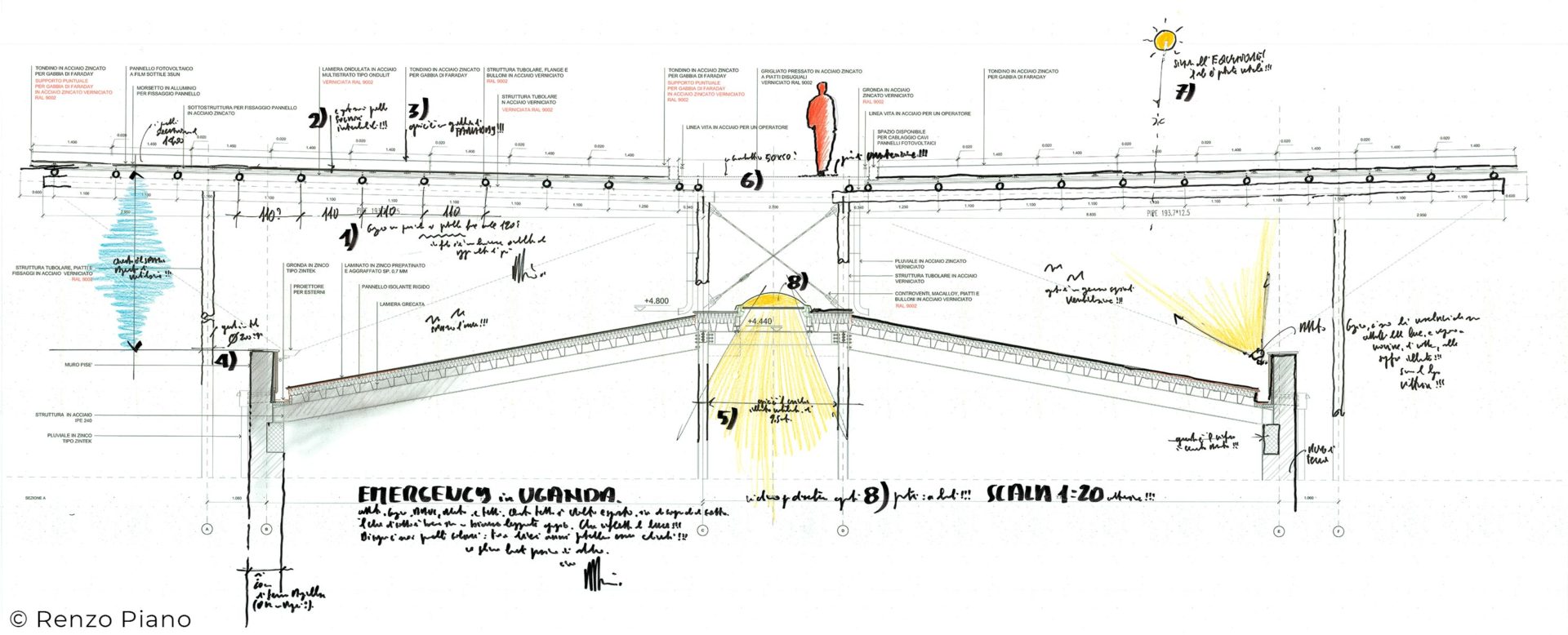

Piano combined the use of earth with the element that has always characterized his vision of architecture as a shelter: a metal framework “umbrella” – actually two large open wings – supporting 3,000 square meters of solar panels that guarantee not only full energetic autonomy for the hospital, but also the possibility of using excess energy to supply the surrounding area.

The actual roofing solution of the building is located under these wings and made of zintek® titanium zinc.

All’uso della terra, Piano ha abbinato l’elemento che da sempre caratterizza la sua stessa visione dell’architettura come shelter: un “ombrello” in struttura metallica – in realtà due grandi ali dispiegate – che sostiene 3.000 metri quadri di pannelli solari, così da garantire non solo la piena autonoma energetica dell’ospedale, ma di utilizzare il surplus per alimentare l’area circostante.

Al di sotto delle ali, la copertura vera e propria, realizzata in zinco-titanio zintek®.

Zintek for EMERGENCY

When EMERGENCY asked us to collaborate in the project for the Entebbe Pediatric surgery center, we were certain of two things: that we had worked well up until that point, and that we were being offered an opportunity to further enrich our story.

Acceptance of the offer and challenge was almost automatic, not only due to the prestige of the operation – a health structure on such a scale in a geographically distant and culturally different country, alongside internationally renowned partners – but above all because the project perfectly marries Zintek’s mission and values.

The promotion of “ethical” architecture focused on man more than anything else is the backbone of our corporate philosophy (it is no coincidence that the company achieved the SA8000 certification, based on principles established by the Universal Declaration of Human Rights, by International Labor Organization treaties and by the Convention on the Rights of the Child), and the source of our strong sense of responsibility towards society and unassailable faith in the idea that we truly can make a difference in the world.

This is why we always offer pro bono collaboration in initiatives aiming to recover, protect and improve the environment, intended both as natural landscape and as the places we live in every day.

Donating (time, know-how, products, the strength of an entrepreneurial group) is an integral part of who we are, as only by donating and sharing can we circulate ideas, aspirations and convictions, giving birth to new experiences. We believe that donating entails giving one’s best: as stated by Renzo Piano and Gino Strada, one should never donate anything less than excellent.

Over time , we have become experts in excellence: from our fully certified zintek®, a long-lasting and resistant product capable of ensuring high residential comfort standards and timeless beauty, to the quality of our technical and organizational consultancy services, without forgetting the communication skills we are proud to have developed over the years.

This experience has shown us that good deeds are possible. Yes, diverse actors can collaborate outside of traditional canons and their respective “comfort zones” with exceptional results. Yes, they can work to achieve “ethical” profits rather than economic ones, receiving in exchange confirmation that the “goodness” of practices and feelings has the power of making the change for the better we’d all like to see (and unfortunately so often remains confined to words only) real.

Gino Strada & Renzo Piano

Speaking of the idea behind the project, Gino Strada states that:

“There is a widespread idea that if I need to make a chair for my home, I will design it perfectly on level with four legs and a comfortable edge; but if I need to make it for Africa, it only needs to be good enough for leaning on. This is not acceptable: the best way of practicing equality – in Africa and elsewhere – is to show people we consider them our equals, beyond any political convenience of the moment. We would like all our buildings to be beautiful, hospitals included, so why should we fill another country with ugly things?”

Renzo Piano answered this call with enthusiasm:

“When I met with Gino Strada to discuss the project, the first thing he said to me was: ‘I want to build a scandalously beautiful hospital!’. We were immediately on the same wavelength, as I have always believed that ethics and aesthetics are two sides of the same medal. Kalós kaì agathós, said the ancient Greeks: physical and moral beauty define an ethical beauty, linked to a notion of justice and opportunity. Actually, social necessity would be more correct. Even in the various African dialects, the idea of beauty goes hand in hand with that of goodness: nothing beautiful can be less than good.”

Focus on the roofing solutions

Anyone who knows Gino Strada and Renzo Piano will be fascinated by the “tectonic dualism” found in the new hospital, as it appears to contain the main characteristics of these two men: the solidity and concrete nature of the raw earth walls, built using the pisè technique, and the lightness of the structure supporting the roofing solution, in steel, dry-applied layers and titanium zinc.

Here, Gravitas and Levitas co-exist in dialectic fashion, emphasizing one another in a sort of technological “yin-yang” where the local construction technique using compacted raw earth goes hand in hand with innovation borne of refined industrialization of metal framing, cladding materials, door and window design and integration with photovoltaic panels to ensure maximum sustainability and minimum environmental impact.

From a cross-sectional standpoint, Renzo Piano’s idea almost resembles a Lake Victoria heron with open wings. These large “metallic wings” are actually the second roof of the building, a sort of elytron acting as a parasol for the roofing solution of the building envelope, and hosting 2,670 sq m of polycrystalline photovoltaic panels that in turn provide the hospital with sustainable electricity.

The roofing envelope is indeed the most technologically advanced element of the construction, requiring detailed and coordinated design efforts. Its function is to prevent the passage of water and air, thus allowing for management of typical temperature peaks at these latitudes (even if the upper second “parasol” roof effectively mitigates direct sunlight radiation shock).

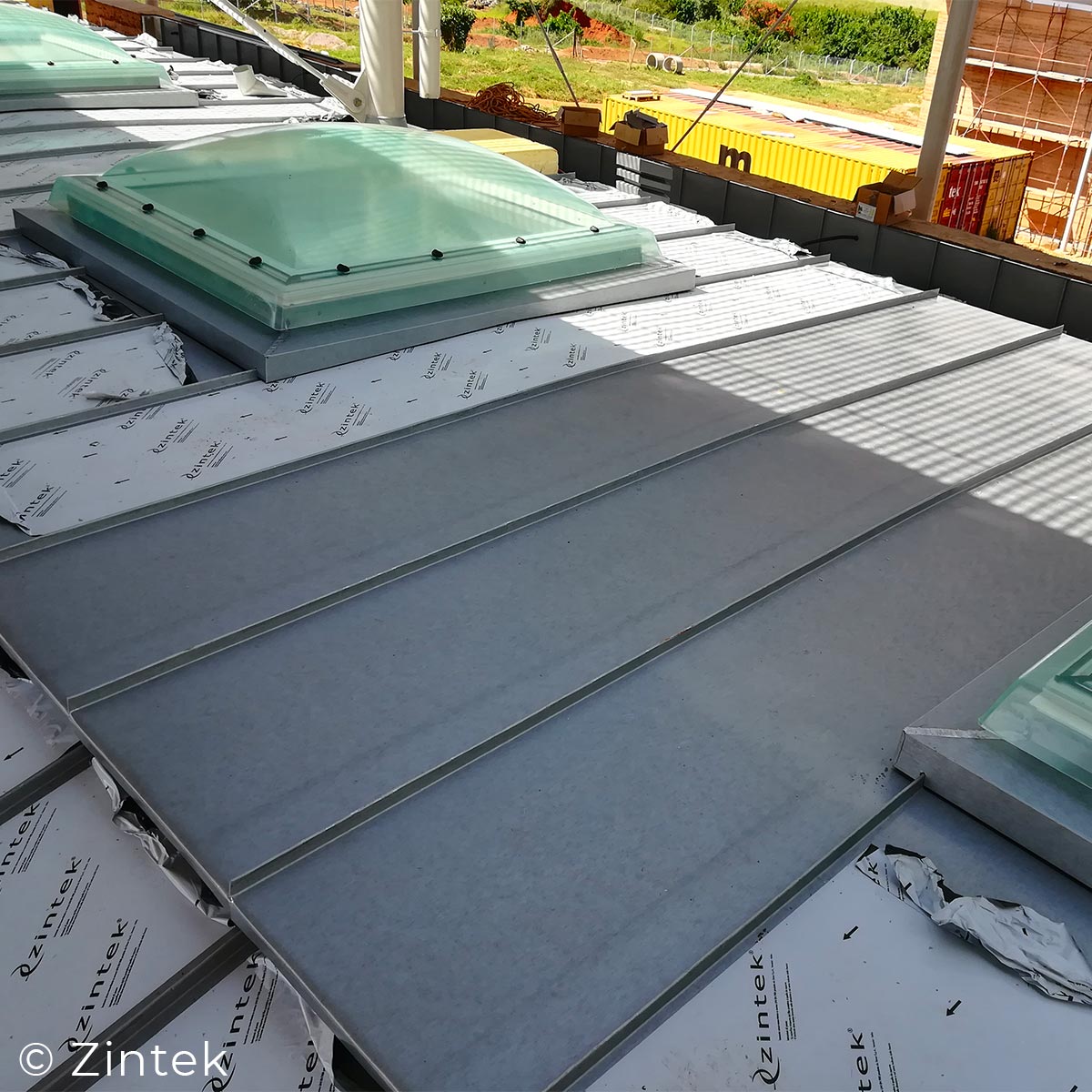

The complex roofing element covering the hospital areas therefore functions as a thermo-acoustic insulation system and is clad on the outside in pre-weathered zintek®.

Renzo Piano defined this material as “splendid and capable of lasting forever. A noble material belonging to the history of architecture and of the city, as can be observed in old Paris, where roofs are made of galvanized sheet metal and repair technicians who work on these structures are called couvreurs. What’s more, this is a material that ages in its very own way, like copper and lead, and all things derived from nature.”

The central flat section of the zintek® titianium zinc roofing solution features 40 Velux skylights which provide zenithal light for the distribution areas. The seaming and overlapping details were curated with particular attention around these points of discontinuity in the roof, to ensure maximum continuity and impermeability.

The decision to avoid the use of materials such as wood – easily targeted by insects and thermites – and to focus solely on mineral and metallic materials played an important part in the choice of system and stratigraphy.

Thus, the designers opted for a roofing package with no ventilation gaps, also in light of the fact that the building is shielded from most solar radiation by the upper “umbrella” roof.

The pitch of the zintek® slabs is equal to 478,5 mm, a submultiple of the main structural mesh, based on the concept of modularity often promoted by Renzo Piano.

The presence of titanium in the alloy increases resistance to deformation over time, while the presence of copper increases tensile strength; the combination of titanium and copper decreases the dilation coefficient of the alloy.

When it comes in contact with water or humidity, zintek® becomes “passive” and generates a layer of highly stable and corrosion-resistant zinc carbonate, which allows for the material to enjoy an extremely long lifespan (more than 100 years in rural environments), as well as low maintenance requirements. Furthermore, the material was supplied in the form of flat slabs and, thanks to its malleability, was processed and cold-rolled with a roller supplied on the containers. The material is also fully recyclable and releases no residues, so the water from the 388 linear meters of zintek® downpipes can be used to irrigate the internal gardens that are part of the treatment project.

In Entebbe we can observe how the need for simplicity, for a “naked” and ethically clean beauty – in light of the treatment- and quality-focused theme set by EMERGENCY and based on the social and natural context – has led the dialogue between Renzo Piano and Zintek to work in a minimal form. The malleability of the material and its workability allowed for optimization in the production of the slabs (in Marghera) and their transportation and logistics, managed via ship prior to installation in the worksite. We are speaking of an actual “supply chain” which allowed specialized installation technicians, sent from Italy, to perfectly enter the worksite process phases and develop the continuous roofing solution, perfectly watertight and without any ventilation gaps, as explained above.

This hospital will be an example for health services in Africa, capable of acting as a model for the future and creating a sort of “emulation” both in terms of treatment procedures and based on how local materials and techniques were integrated with high technology and performance products and materials.

Note: all texts presented in this page were prepared thanks to contributions by Fulvio Irace, Renzo Piano, Gino Strada, Marco Imperadori, Giorgio Grandi and Roberto Crestan. This is why they cannot be copied or reproduced in any form without explicit consent from Zintek.